A3D Insider is Additive Learning’s blog and showcases new trends and technologies and the latest landscape in Additive Manufacturing. On this blog, you will find the latest information and news from the world of additive manufacturing and rapid prototyping apart from some basic questions being answered. Institutes which are a part of the A3D Center of Excellence programs can encourage their students to write articles about recent trends in Additive Manufacturing and also about projects that they have executed in 3D printing or Additive Manufacturing or allied domains.

Additive Manufacturing (AM) is a fabrication method that creates a 3D form via the accumulation of materials. Coupled with computer-aided design (CAD), AM has been popularized in the rapid prototyping and customized design solutions. Although it’s not a new technology in the strictest sense, additive manufacturing (AM) — sometimes referred to as 3D printing — has attracted significant attention in recent years.

Compared to subtractive processes like milling, additive manufacturing generally provides greater geometric freedoms and utilizes less material. In contrast to forming processes such as injection molding or composites layup, 3D printing does not require a mold or other tooling to create a part. Additive manufacturing has been shown to be a good option in production applications where long lead times or associated costs preclude the use of expensive tooling; complexity of geometry is advantageous; and/or low volumes are required, though the quantities appropriate for 3D printing continue to increase.

AM-produced parts are being used in mission- critical situations and in the aviation and power industries where safety and reliability are of prime importance. The parts manufactured using this technology can be more complex than those they replace, with a single AM part replacing several others. While some quality testing of these parts can be undertaken using existing methods, AM parts also present unique

The purpose of the testing is the same whatever the method of manufacture. However, the differences between the product of the two methods (AM or non-AM) are significantly different as AM parts are produced in thin layers, rather than as a full-body object.

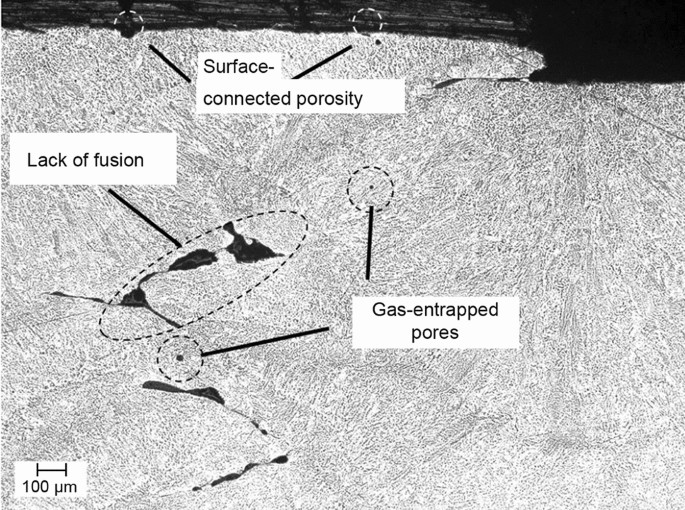

The textured surface of AM-produced parts renders most surface inspections impossible as superficial artifacts will be mistakenly identified as cracks. Of the tests currently available to validate parts, those most useful for AM manufacturers are radiographic internal inspections.

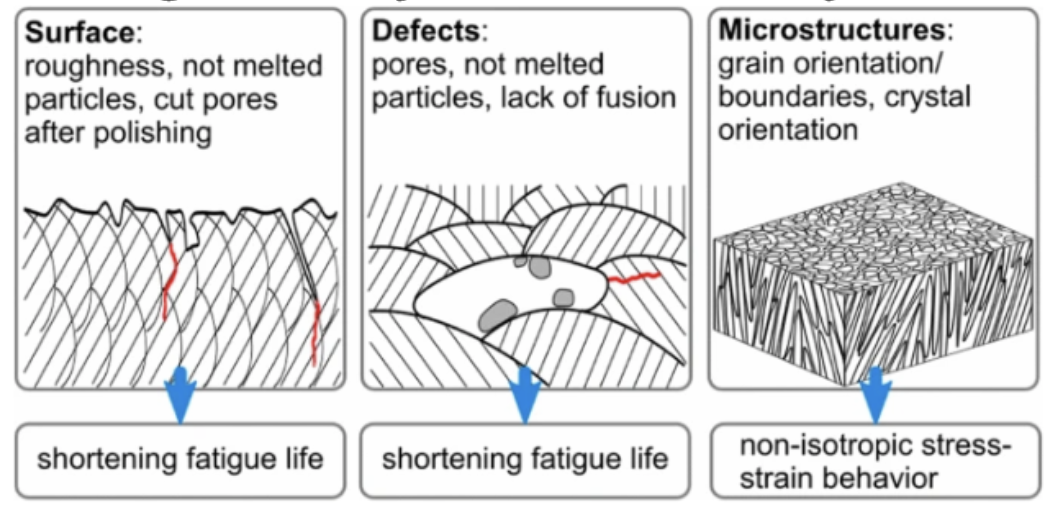

Defects in AM parts: Occurrence of defects leads to inferior mechanical and other properties of the fabricated parts. Given below are some common defects in AM parts.

Porosity: Porosity Most of the binding mechanisms are associated with temperature variations under capillary action and gravity without the aid of external forces. A few causes for porosity/void defect is recurrence of keyhole emergence, gas entrapment leading to microscopic pores during atomization, insufficient penetration of subsequent layers into substrate, etc

Cracks: Another commonly occurring defect in parts fabricated by fusion based AM processes are cracks since metals swiftly melt and solidify during these processes [378]. Owing to this fast cooling, large temperature gradients and correspondingly large thermal residual stresses generation occurs. Large residual stress when combined with high temperature gradient lead to crack initiation. Cracks are especially prominent along grain boundaries since temperature varies for each layer, i.e., substrate, solidifying and deposited because of varied contraction rates

Distortion: Distortion defect occurs in AM parts if stress development takes place in material owing to volume shrinkage

Balling phenomenon: The balling phenomena also called as bead up is a defect where underlying surfaces are not wetted by liquid material and results in occurrence of beaded scan track thereby increasing surface roughness as well as tendency to form pores

Residual stresses: In AM processes, the temperature of the metal powder varies considerably and thermal stresses easily form within the component, causing significant uncertainty with regards to the quality of the final part. When the stresses trapped inside the component are suddenly released, cracks emerge on the surface, affecting the performance and life of the component.

Materials for Additive Manufacturing: Additive manufacturing is based on the materials. In order for additively manufactured components to be viable for functional use, improvements need to be made in terms of process quality and reliability. As additive manufacturing moves beyond rapid prototyping, there is a need to tune specific material systems for specific applications. Using new special consumables materials is the main development direction of Additive Manufacturing.

Polymers: AM using polymers can be carried out successfully using a variety of polymer materials in different forms and compositions including their composites, nanocomposites, continuous/discontinuous fiber-reinforced thermoplastic composites, and hybrids. The most common thermoplastic polymer materials used in FDM processes are acrylonitrile butadiene styrene (ABS), polylactide (PLA), polyamide (Nylon), nylon 12, polycarbonate (PC), glass-filled nylon, and epoxy resin. Some of the commercial polymer materials that are most popular in the FDM process include ABS_M30 and polycarbonate (PC). In SLS and multi-jet, most commonly Polyamides (Nylon PA 11 and Nylon PA 120 and thermoplastic polyurethane (TPU) are used. For the SLA technique various photo-active special polymers have been developed. The polymers used in AM processes can be rationally classified as thermoplastics, particle reinforced polymer composites, polymer matrix composites, fiber-reinforced polymer composites, thermo-responsive polymers, nanocomposites, and thermoplastic elastomers composites.

Polymer matrix composites (PMCs): are generally comprised of various fibers, which are either short or continuous, that are bound together by using an organic polymer matrix. The reinforcement of polymers with fibers and particles was introduced to increase the mechanical properties of the polymer so that they can be used in load-carrying applications. These polymers include synthetic and biomaterial resins. Polymers are reinforced using carbon-based materials. FDM has been commonly used for the fabrication of such reinforced polymer composites. Some of the reinforcement materials used in FDM are TiO2, carbon nanofibers, montmorillonite clay, graphene, etc. The reinforcements used in the SLA process are carbon nanotubes, graphene oxide, TiO2, BaTiO3, etc.

Particle Reinforced Polymer Composites: Particle reinforced composites consist of the dispersion of particles of one material into the matrix of another material. These particles may vary in shape, size, and morphology. However, they are generally sphere, oval, polyhedron, or irregular in shape. The process of forming particle composite comprises of adding particles to the liquid matrix, which solidifies later, growing them in place using procedures such as age hardening, pressing together, and then inter-diffused by means of a powder process, etc. The composite powders are prepared by processes such as cryogenic ball milling, emulsion-precipitation, wet grinding-rounding, spray drying, and dissolution-precipitation.

Fiber Reinforced Polymer Composites: Fiber-reinforced composites (FRC) are composite building materials that consist of three components namely the fibers, the matrix, and the interface. Composite materials are produced by combining two or more materials with different properties so that better properties that cannot be achieved by either fiber or matrix separately are achieved. The mechanical properties of the fiber-reinforced composites are dependent on the strength and modulus of the fiber, chemical stability, and the quality of the interfacial bonding between the fiber and the matrix.

Nanocomposites: The combination of nanotechnology and AM enables manufacturing of 3D parts with optimized properties and multi-functionality. The incorporation of nanomaterials such as carbon nanotubes improves the electrical conductivity, mechanical strength, and electromechanical and chemical sensitivity. A variety of 3D nanocomposites are manufactured using AM technologies for various applications in different fields including microelectromechanical systems (MEMS), microfluidics, engineered materials and composites, micro-electronics, lab-on-a-chip, biosystems, and tissue engineering. The common additive manufacturing methods used for manufacturing nanocomposites include micro-stereolithography, extrusion-based technologies, inkjet printing, and powder bed technologies.

Metals: Metals are often used in various forms, including wire and in powdered form, to create simple and complex 3-D objects. Due to advancing technologies, other metal forms have been used such as rods and filaments. Metals used in manufacturing are often non-reflective. Non- reflective metals do not reflect light away or back to its source. Since some additive manufacturing processes use lasers or ultraviolet light to heat, melt, or cure materials together, a reflective metal would send the laser or UV light back to its source. So the metal materials would not bond to each other and could damage equipment.